Why Timber?

Style

Timber is timeless. Timber is contemporary. Timber is stylish. Timber gives the maximum flexibility in Design.

Our European forebears used time-honored timber for their windows, doors, and claddings, traditionally working in Oak, Larch, and Nordic Redwood. We are proud to continue that tradition and offer the same materials, complemented with modern, technically enhanced timbers. Always durable.

Those timbers include Accoya®, and thermally modified (TM) timbers, Abodo®, Cambia® Ash, TM Oak and TM Poplar. Also classic Australia timbers such as Spotted Gum, Blackbutt, Silver Top Ash, and Blackwood (internally). In this way we can offer a broad range to integrate both external cladding considerations, and internal design.

We in-house laminate all our timber as solid three or four layer configurations which enables an infinite range of design and style options.

We are passionate about the performance, quality, and sustainability of timber. We NEVER use Victorian Ash hardwoods, Western Red Cedar, New Guinea Rosewood, Meranti, Merbau, as they are compromised in durability or source sustainability.

Energy Efficiency

When formatted correctly and incorporating the best materials and finishes, timber windows and doors offer the best thermal performance. Our products don’t just feel warm they are warm. Timber is cool and stays cool.

Glazing for energy efficiency

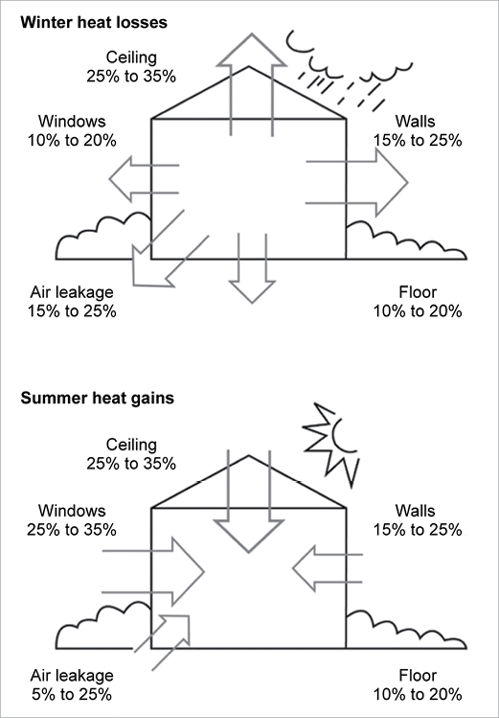

Windows and doors require special consideration when planning an energy-efficient and comfortable home. Glazed areas can take up a large proportion of exterior walls in a building and if these glazed areas or the material that supports them are inferior, the thermal integrity of the house as a whole is compromised.

Timber is insulating

Compared with metal, timber has a very low thermal conductivity. Steel is 100 times more thermally conductive, whilst aluminium is 2000 times more thermally conductive. By using local hardwoods which has the strength of steel, we can build large fenestration elements that boast outstanding performance.

In 2010 we were an early adopter of Accoya® timber, with extremely low thermal conductivity of 0.12 W/mK, and outstanding durability, with a guaranteed service life of 50 years. It's typically our first choice external timber.

We also uses Thermally Modified (TM) timbers: Abodo®, Cambia® Ash, TM Oak and TM Poplar (Tulipwood).

We also offer a range of FSC, PEFC sustainable timbers.

Internally we use a range of timbers for either thier insulating or visual features. Depending on availability and suitability, we also source recycled timber.

Making the Modernist “glass box” very comfortable

Our timber curtain wall system is Passive House Institute Certified Component. We use up to 50mm thick triple-glazed, insulated glass units to a very low Ug-value of 0.5 W/m2K (R-value 2.0 m2K/W). We optimise all triple glazing for Australian conditions to minimise glare and reduce heat gain where needed.

Let's talk R-Values

By comparing these R-Values below, it is easy to see that all the energy - goes right in/out the windows & doors!

- Roof: R-value of 4 m2K/W

- Walls: R-value of 2 m2K/W

- Floor: R-value of 1 m2K/W

Given all the heat losses through windows in Winter, we should target windows with an R-Value of at least 1 m2K/W, so that's a U-value of 1 W/m2K. To match the wall insulation performance, with very large glazed areas, we suggest our triple glazed systems to an outstanding R-value of 2.0 m2K/W.

In Summer must significantly reduce the heat gain. We advise high-performance insulated glass units with low-emissivity coatings (high in reflectivity), ideally on two or more surfaces; with low Solar Heat Gain Coefficient (SHGC).

We only use the highest performing Low-E double and triple glazed insulated glass units to give the best performance. Insulated glass units are a minimum of 28mm deep for double glazed; 36mm for triple glazed to 50mm.

As every orientation of a building is different, we specify different glass to optimise the performance.

Durability

Australian conditions are tough on timber, no matter where you live in an urban or rural area. A timber material must be able to resist and withstand any environment it may encounter. Naturally durable timbers do just this well.

Timber - Natural Durability Ratings

| Durability class | Above-ground life expectancy | In-ground life expectancy |

|---|---|---|

| 1 | > 40 years | > 25 years |

| 2 | 15 to 40 years | 15 to 25 years |

| 3 | 7 to 15 years | 5 to 15 years |

| 4 | 0 to 7 years | 0 to 5 years |

We typically use Class 1 timber externally. Our bespoke timber material choices optimises for durability. Our unique, in-house lamination process includes highly durable timbers such as Accoya®, Thermally Modified (TM) timbers, and Spotted Gum or Blackbutt for BAL requirements.